Table of Contents

Report

Title : Autonomous Sailing Boat

Author(s):

- Roberto Giordano

- Gary Jonathan Rabone

- Marc Navarrete Hill

- Imre Asztalos

- Thies Gunther

Acknowledgement

Finishing the 4 months project of the autonomous sail boat, we want to thank all the teachers involved in the different classes taught, as well as the supervisors that guided us patiently and competent through the whole project. It was for all of us a great experience full of hard work, great companionship that extended at the end our horizons in on a cultural and also educational level. Furthermore we are thankful that the “Instituto Superior de Engenharia do Porto” (ISEP) offered us the chance to stay in Porto and do the European Project Semester (EPS). A special thanks to Fernando Ferreira who was a great support throughout the whole project. He guided us towards the accomplishment of the project and ensured the correct progress.

Abstract

At present, the ocean suffers greatly as a result of ever-growing population and disasters occur all over the world. A manoeuvrable ocean exploring monitoring system has been a state of the art subject for several years. The advancements in the field can be used in several market sectors and developed overtime. This system can be used for research and development purposes. The system can monitor oceans while maintaining the desired energy efficiency measures. Horizon Sail is developing an innovative rigid-wing for a sailboat likely to sail the oceans and capture data without human interaction. The product will be marketed on several platforms to be used widely in several industries. Many technical aspects still have to be studied and developed, especially regarding the boat that will be subjected to adverse climate conditions in unmanned areas and reducing the human assistance if damage occurs.

Abbreviations

| Abbreviation | Description |

|---|---|

| 4P | Product, Place, Price and Promotion |

| ${a_1}$ | Distance from Hull and Top of the Mast |

| ${a_2}$ | High of the Geometrical Centre of the Reefed Sail |

| Ah | Ampere hour |

| AIDA | Attention, Interest, Desire and Action |

| AIS | Automatic Identification System |

| AMS | Autonomous Marine System |

| AP | Aft Perpendicular |

| ${A_x}$ | Maximum Section Area Below Designed Waterline |

| B | Beam |

| ${B_1}$ | New Buoyancy Centre |

| B2B | Business to Business |

| B2G | Business to Government |

| BD | Boom Height Above Deck |

| ${B_{WL}}$ | Beam of Waterline |

| CANbus | Control Area Network |

| ${C_B}$ | Block Coefficient |

| CB | Centre of Buoyancy |

| CCS | Carbon Capture and Storage |

| ${C_D}$ | Drag Coefficient |

| CE | Aerodynamic Centre of Effort |

| ${C_F}$ | Skin Friction Coefficient |

| CG | Centre of Gravity |

| CHP | Combined Heat and Power |

| ${C_L}$ | Lift Coefficient |

| CLR | Hydrodynamic Centre of Lateral Resistance |

| ${C_{Lr}}$ | Rudder Lift Coefficient |

| CNC | Computer Numerical Control |

| ${CO_2}$ | Carbon Dioxide |

| CP | Prismatic Coefficient |

| CS | Carbon Capturing System |

| d | Distance |

| D | Drag |

| dBm | Decibel-Milliwatts |

| DFA | Design for Assembly |

| DFD | Design for Disassembly |

| ${D_{WL}}$ | Designed Waterline |

| EEPROM | Electrically Erasable Programmable Read-Only Memory |

| EMAS | European Management and Audit Scheme |

| EPS | European Project Semester |

| EU | European Union |

| ${F_1}$ | Hydrodynamic Force |

| ${F_A}$ | Aerodynamic Force |

| ${F_h}$ | Horizontal Boom Force |

| ${F_{LAT}}$ | Aerodynamic Side Force |

| ${F_M}$ | Driving Force |

| FoS | Factor of Safety |

| FP | Forward Perpendicular |

| ft | Feet |

| ${F_V}$ | Vertical Boom Force |

| G | Centre of gravity |

| GDP | Gross Domestic Produce |

| GPIO | General Purpose Input/output |

| GPRS | General Packet Radio Service |

| GPS | Global Positioning System |

| GSM | Corporate Telephone Preference Service |

| GUI | Graphical User Interface |

| GWh | Giga Watt hour |

| h | Height |

| HMI | Human Machine Interface |

| ISEP | Instituto Superior de Engenharia do Porto |

| ISO | International Organisation for Standardisation |

| i/o | input/output |

| kg | kilogram |

| l | Horizontal Length of Rudder at Centre of Effort, or Long Span of Panel, or Stiffener Length |

| L | Lift |

| LCB | Longitudinal Centre of Buoyancy |

| ${L_{OA}}$ | Length overall |

| LOBO | Land/Ocean Biogeochemical Observatory |

| ${L_{PP}}$ | Length Between Perpendiculars |

| LSA | Autonomous System Laboratory |

| ${L_{WL}}$ | Length of waterline |

| M | Bending moment, or metacentre |

| m | Meter |

| ${M_1}$, / ${M_2}$ | Motor 1/2 |

| MHz | Megahertz |

| MIS | Management Information System |

| ${M_r}$ | Rudder Bending Moment |

| MW | Mega Watt |

| N | Newton |

| NACA (NASA) | National Advisory Committee for Aeronautics |

| NERC | National Environment Resource Council |

| NIST | National Institute of Standards and Technology |

| NOC | National Oceanography Centre |

| ɵ | Heel angle |

| P | Height of Mainsail (IOR), or Propeller Pitch, or Load, General |

| ${P_a}$ | Dimensioning Aft Stay Load |

| ${P_{fo}}$ | Dimensioning Outer Forestay Load |

| Pi | Rasperry Pi |

| ${P_{LAT}}$ | Hydrodynamic Side Force |

| PSC | Programmable Servo Controller |

| PWM | Pulse Width Modulation |

| R&D | Research and Development |

| RADAR | Radio Detection and Range |

| ${R_F}$ | Frictional Resistance |

| RM | Righting Moment |

| ${R_n}$ | Reynolds Number |

| ROHS | Restriction of Hazardous Substances |

| SD | Secure Digital |

| SDK | Software Development Kit |

| SRAM | Static Random-Access Memory |

| S.W.O.T | Strengths, Weaknesses, Opportunities and Threats |

| SAN | Styrene Acryrin |

| SI | International System of Units |

| ${S_W}$ | Wetted Surface Area |

| T | Draft |

| ${T_1}$ | Wave Period, or Transverse Foresail Force |

| ${T_2}$ | Transverse Mainsail Force |

| ${T_{boom}}$ | Transverse Force at Foot of Mainsail |

| ${T_{bu}}$ | Upper Boom Force |

| ${t_c}$ | Core Thickness |

| ${T_{head}}$ | Transverse Force at Top of Mainsail |

| ${T_{hl}}$ | Lower Shroud Force |

| ${T_{hu}}$ | Upper Shroud Force |

| TWh | Tera Watt Hour |

| UART | Universal Asynchronous Receiver/Transmitter |

| US | United States |

| USB | Universal Serial Bus |

| V | Volt |

| ${V_A}$ | Apparent Wind Directions |

| ${V_d}$ | Volume Displacement |

| VOC | Volatile Organic Compounds |

| ${V_S}$ | Yacht Speed (m/s) |

| Wh | Watt Hour |

| WIPE | World Intellectual Property Organisation |

| XML | Extensible Markup Language |

| WOW | Wally Over Wing |

| X, Y, Z | Cartesian Coordinates, Origin at FP, X Afterwards, Y to Starboard, Z Vertically Upwards |

| α | Angle of Attack |

| λ | Wavelength or Taper Ratio |

| ρ | Density |

1. Introduction

“Talent wins games, but teamwork and intelligence win championships.” - Michael Jordan

1.1 Presentation

Our team consists of five multinational, interdisciplinary student members who have undertaken the European Project Semester programme 2015 at the Instituto Superior de Engenharia do Porto otherwise known as ISEP. The programme commenced on the 23/02/2015 and it will last four months, finalising on the 26/02/2015. The semester is based on a group project, “Autonomous Sailing Boat”.

The programme also offers additional classes such as Team building, Project Management, Communication, Marketing, Sustainability and Ethics & Deontology all of which are designed to aid the project completion.

Our Crew

Table 1 displays our crew.

Figure 1 displays our first idea of a sailboat.

1.2 Motivation

The decision to select a suitable project which covered all our skill sets was a difficult one out of the 15 project proposals. The final choice was to design, manufacture and deliver an autonomous sailboat to a client who specialises in the field of autonomous systems. The motivation for our team decision is based on several conditions, listed below:

- Team Contribution: It takes a lot to make people a winning team. Everybody's contribution is important and this is vital in achieving our combined goal.

- Innovation: For good ideas and true innovation, you need human interactions, conflict, argument and debates. This is something we all possess as a team and through thick and thin we will achieve new heights with this project.

- Challenge: Overcoming a problem takes time and effort but more importantly team support. The cooperation each member plays in our team will contribute to our overall success and each individual will be supported throughout to overcome any challenges faced.

Each team member also had their say:

- Roberto Giordano: “I selected this project to better understand an ancient but still modern mode of transportation, traditional and common but also exciting. With this project I can improve my practical skills and work on something tangible and that can be useful for everyday life.”

- Gary Jonathan Rabone: “I chose the project due to its challenge and relevance to my field of study, furthermore its appeal was grown by working with an accomplished institute in the autonomous control system sector.”

- Marc Navarrete Hill: “I selected that project because I immediately recognised that I could implement all the design skills that I have currently studied during my advanced education and moreover because the sea is one of my passions and always wanted to design a naval mode of transport.”

- Imre Asztalos: “Every summer I go sailing so this project was very attractive since it is one of my favourite hobbies. I'm looking forward to using my sailing and electronic knowledge in this project. I think this project is not easy, but it will be a very good experience for all of us in the team.”

- Thies Gunther: “The project was appealing I had the feeling that in our interdisciplinary team everybody could contribute to the project. Due to the fact the technology of the autonomous sailing is relatively new, we all can benefit from the knowledge of new technology.”

1.3 Problem

Although none of our members is specialised in naval engineering, we felt that there is a strong market need for autonomous sailing boats. There is a high interest in doing research missions in all different water environments and doing this autonomously would enhance our possibility in the market. Therefore we have to first think about the actual mission that the boat has to fulfil. Based on this we need to define the dimensions of the boat and select the best and cost efficient material. Meanwhile we have to research the best possibilities to design the hull and start off with calculations as well as simulations to ensure safety and stability of the boat in its diverse environments. Doing so, we will take into account the size of the sail and the total weight of the boat to ensure the maintenance of buoyancy in any rough water surrounding. Lastly there is the aspect to guarantee a steady power supply to be autonomously and accomplish its long term missions.

1.4 Objectives

The objective of this project is to build a boat that has the ability to store and collect data in a changing environment. The boat shall be able to stay in a prior defined area for a longer time (months). The environment can be any possible body of water such as ocean, lakes or river. The focus is to design a boat that is extremely stable and reliable when completing its various missions. It is key for the modular design of a control system that is adjustable for different sensors or even cameras. The sail shall consist of a rigid wing-sail and the boat shall not exceed the dimensions of 3 meters. Due to an easier navigation it only consists of one rudder. Furthermore we have to find different power supply solutions to ensure a constant functioning of all electrical components. Besides we will have to do a market research to find prospective clients and purposes that our boat will be able to fulfil. Our target is to design a boat that is, in respective to sustainability, environmentally friendly.

1.5 Requirements

There are a number of requirements that the boat intend to adhered to:

- The boat has to withstand adverse environmental conditions while in operation.

- It must be unsinkable and retraceable if damaged.

- Backup motor system for zero wind conditions.

- Capable of venturing on missions for extensive periods of time.

- The boat must comprehend and accommodate autonomous components such as sensors for wind, depth, current and location.

- Single rigid sail and single rudder boat.

- The boat must operate in a certain area.

- Sustainable methods of power through the environment. (wind, solar, currents)

- A 1:1 scale model must be designed, (1) Styrofoam prototype (2) Final Product.

Comply with the following EU Directives:

- Machine Directive (2006/42/CE 2006-05-17);

- Electrical Safety: Low Level Voltage Directive (2006/95/CE 2006-12-12);

- Restriction of Hazardous Substances (ROHS) in Electrical and Electronic Equipment Directive (2002/95/EC 2003-01-27);

Mandatory adoption and use of the International System of Units (SI) (The National Institute of Standards and Technology (NIST) International Guide for the use of the International System of Units (SI)).

1.6 Functional Tests

The model and final product will be subjected to a variety of tests to ensure its integrity in its requirements to for fill the desired roles of the client. The main tests that will be undertaken are buoyancy for the hull and lift on the sail. We are also going to test the boat as a whole to ensure these functional test cooperate to allow the boat to be fully functional. It is a necessity to have to check if all the used components are correctly positioned and assembled during these tests to avoid inaccurate data.

1.6.1 Buoyancy Test

Conducting this test will validate our boat design from geometry and weight predictions from materials and components. This test we will use the water tank in the LSA laboratory. The main idea is to see if we balanced our boat the right way and if the material used is causing an appropriate buoyancy. The boat will have a prefixed maximum capacity of 60 kg, to ensure our boat is viable in this test we will fill the boat with 70 kg plus an exceeded weighted body as a tolerance, this will validate that the boat will float when exceeded weight is applied. This test will ensure if any future upgrades to components of unexpected weight will be accepted by the boat. The keel and hull have to be calculated and designed the right way as our learning outcome of the State of the Art chapter taught us.

1.6.2 Sail Lift Test

This test will consist of the rigid wing sail stalled in position with a variety of weights applied to a pulley. The lifting force will be calculated from the amount of weight, which it can lift off the ground. The driving force will be a fan obtained form LSA to adjust the lifting force in particular angles and positions. The fan will be positioned to cover the maximum surface area for the initial test. This will ensure the rigid sail is functioning correctly and also giving the boat an appropriate velocity. We have to make sure that this is done in a secure area so we do not lose the boat or it will be destroyed in the first place.

1.6.3 Boat/Sail Manoeuvrability

This final test will validate the product to the customer and shareholders as a success. The test will consist of the assembly of hull and sail finalising the boat, it will be subjected to a body of water and controlled via fans positioned in different areas. The boat must manoeuvre through a subject area without deviating from the path to be considered successful. This test will take a vast amount of preparation and team work to be achieved. The help of LSA will be greatly appreciated as an expert body to oversee our test.

1.7 Use Cases

The boat may be used entirely autonomously and be powered sustainably from the environment this can be depicted in the image below Storyboard I. It may also be used in an array of applications which are specific to the user, an example of these can be shown below in the Storyboard II.

Figure 2 Storyboard I

Figure 3 Storyboard II

Below is a detailed list of the possible areas of application:

- Research & Development

- Sea Ice Movement

- Water

- Levels

- Temperatures

- Condition

- Quality

- Animals

- Marine mammal monitoring

- Ocean survey and mapping

- Meteorological data collection

- Health & Safety

- Search and rescue (Both in natural and manmade disasters)

- Deliver humanity aid

- Security & Defence

- Piracy

- Terrorism

- Drug interception

- Environmental & sanctuaries enforcement

- Waste disposal monitoring

- Endangered species monitoring

- Mine Wind farms

- Energy Sources

- Offshore

- Wind farms

- Oil rigs

- Aquaculture

- Aquatic plants

- Farming

- Fish

- Crustaceans (Shrimp)

- Molluscs (Mussels/Oysters)

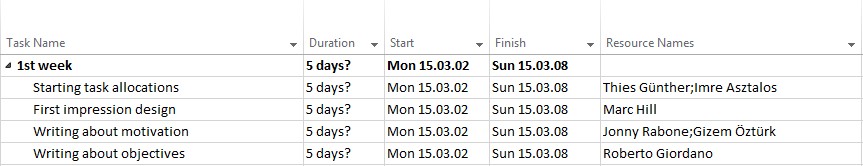

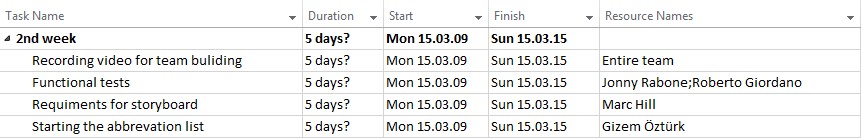

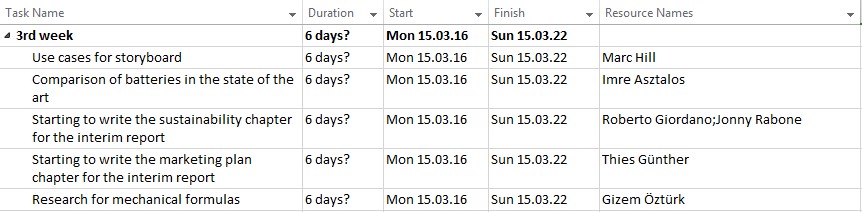

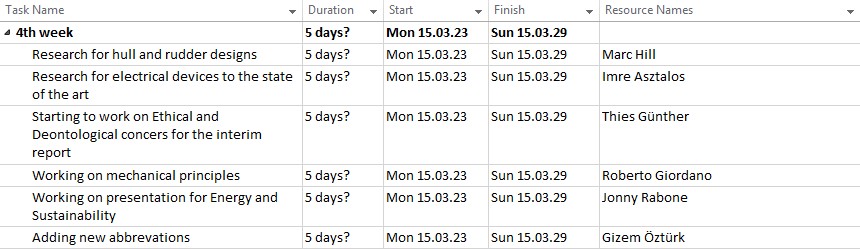

1.8 Project Planning

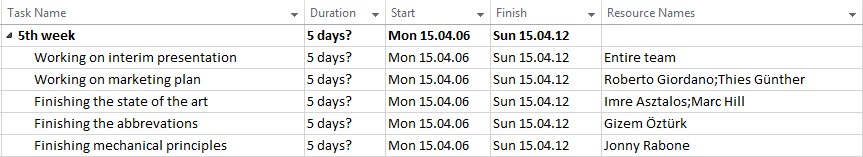

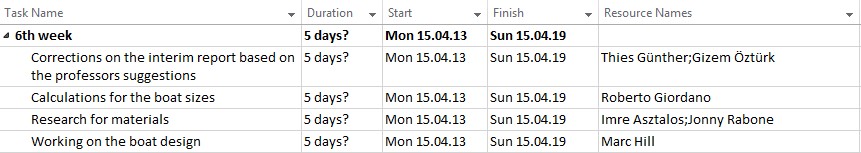

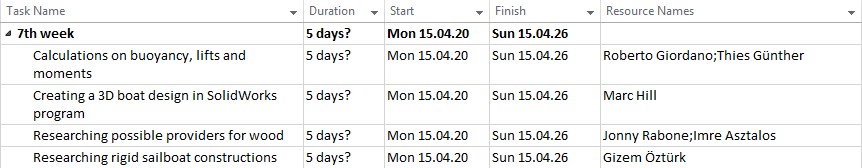

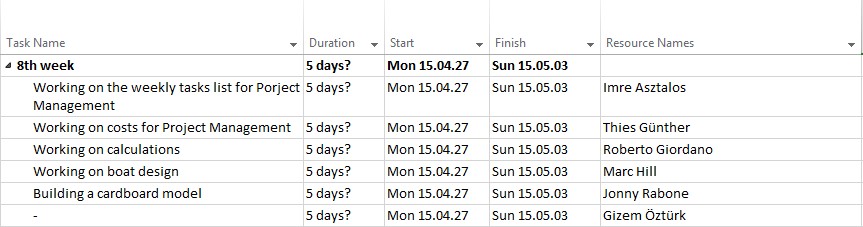

The initial timescale and scope can be seen below in the Gantt chart format of the project. The entire project has been taken into consideration and milestones and markers have been left out to ensure the each task is completed on time and to an adequate level before submission. The Gantt chart below is an alternative one to the Gantt chart done by Microsoft Project, which you can find in the Planning chapter of the report.

Table 2 displays our alternative Gantt chart

Table 3 is demonstrating how we organised ourselves throughout all different tasks and deliverables

| Task | Responsible |

|---|---|

| Gantt Chart | Thies, Imre |

| Leaflet | Thies |

| Poster | Thies |

| Paper | Jonny, Roberto |

| Research materials | Jonny, Marc and Roberto |

| State of the Art | Roberto, Marc, Jonny, Imre, Thies |

| Project Management | Thies, Jonny |

| Marketing Plan | Thies, Roberto |

| Logbook | Jonny |

| Sustainability | All |

| Ethical and Deontological Concerns | Thies |

| Project Development | Roberto, Jonny, Marc, Thies |

| Design | Marc |

| Investigation | All |

| Team Presentation | All |

| Final Presentation | Marc |

| Interim Presentation | Thies |

| Interim Report | Thies |

| Final Report | Thies |

| Development | All |

| Functional Testing | All |

1.9 Report Structure

Table 4 displays the report structure.

| Task | Description |

|---|---|

| Introduction | Consists of a team presentation and the motivation for choosing the project. Furthermore it states the objectives, planning, requirements and the problem which we face. |

| State of the Art | Should give an overview of the mechanical principles and design basis for constructing a sailboat. |

| Project Management | In this chapter we will outline the planning of the project ensuring a successful ending. |

| Marketing Plan | This chapter will consist of an analysis of potential market segments to guarantee a long lasting and profitable surviving in the market of autonomous sailboats |

| Eco-Efficiency Measures for Sustainability | We will try to manufacture Eco-efficient and sustainable for protecting the environment. Therefore we concentrate in this chapter in finding the best solutions for doing so. |

| Ethical and Deontological Concerns | We want to operate ethically correct in terms of setting up a business and therefore we will analyse how to achieve this goal. |

| Project Development | This part of the report will describe the development of our project throughout the semester. |

| Conclusions | Summary of our learning outcomes and the final prototype. |

2. State of the Art

2.1 Introduction

In this chapter we are going to build the basis for understanding and proceeding with our project. We will point out the main ideas and concepts of sailboats and their design. Firstly we will concentrate on the different components of a sailboat such as the hull, mast, sail, keel and the rudder. This will be done by a comparison of the mainly used types and explanation of the principles how these components work on a sailboat. Later in this chapter we focused on the mechanical principles of a sailboat with its hydrodynamics, aerodynamics and equilibrium in both a static and dynamic environment. Our knowledge is based on books on yacht design principles and scientific papers found online. The end of this chapter will contain a conclusion summing up our investigation outcomes and providing design solutions for our project.

2.2 Boat Components

2.2.1 Hull

A hull is the watertight body of a ship or boat. Above the hull is the superstructure and/or deckhouse, where present. The line where the hull meets the water surface is called the waterline. The structure of the hull varies depending on the vessel type like flat or vee bottom these traditionally are monohulls, but multi-hull catamarans and trimarans are gaining popularity. Below is a table which represents a variety of hull types:

| Type | Description |

|---|---|

| Flat Bottom Boat | Flat bottom boat - These boats are generally less expensive to build and have a shallow draft (the part of the boat that's under the water). They can get up on plane easily but unless the water is very calm they tend to give a rough ride because of the flat bottom pounding on each wave. They also tend to be less stable and require careful balancing of cargo and crew. Examples of flat bottom boats might be Jon boats, small utility boats, and some high speed runabouts. |

Vee Bottom Boat  | The vee bottom tends to have a sharper entry into the water which provides for a smoother ride in rough water. They do, however, require more power to achieve the same speed. Many runabouts use the vee bottom design. |

Round bottom boat  | These move easily through the water, especially at slow speeds. They do, however, tend to roll unless they are outfitted with a deep keel or stabilisers. Many trawlers, canoes and sailboats have round bottoms. |

Multi Hull-Boat  | Catamarans, trimarans, pontoon boats and some house boats use a multi-hull design. The wide stance provides greater stability. Each of the hulls may carry any of the above bottom designs. |

Cathedral Hull Boat  | Boats with cathedral-hulls have a distinct modification of the “V” bottom that is called tri-hulls and cathedral hulls. Examples: modern boats usually power driven. This popular hull style has two or more hulls attached closely together for more stability without extra width. The air pocket between the hulls can also help the boat get on plane more easily. Cathedral hull gives a rougher ride in choppy water because of the increased surface at the bow. The side hulls can cause pounding, resulting in a lot of spray. |

With this considerations, and after visiting the “Sport Clube Do Porto”, and in particular the 2.4 metre sailboat we can say that the majority of sailboats have a Vee Bottom Hull or Round Bottom Hull with some adjustments for hydrodynamics.

Figure 4 displays the hull of the 2.4 metre sailboat

2.2.1.1 Hull Features

The hull can be described by dimensional quantities as length, beam and draft, or non-dimensional like prismatic coefficient or slenderness ratio. These dimensional quantities are:

- Length overall (LOA) the maximum length of the hull.

- Length of waterline (LWL) and the length of the designed waterline (DWL).

- Length between perpendiculars (LPP). The forward perpendicular (FP) is the forward end of the designed waterline, while the aft perpendicular (AP) is the centre of the rudder stock.

- Rated Length (RL). The single most important parameter in any rating rule. Usually RL is obtained by considering the fullness of the bow and stern sections in a more or less complex way.

- Beam (B or Bmax). The maximum beam of the hull excluding fittings, like rubbing strake.

- Beam of waterline (BWL). The maximum beam at the designed waterline.

- Draft (T). The maximum draft of the boat when floating on the designed waterline. $T_{c}$ is the draft of the hull without keel.

- Depth, the vertical distance from the deepest point of the keel to the sheer line. $D_{c}$ is without the keel.

- Displacement, could be either mass displacement (m), or the volume displacement (V). It is the weight of water equivalent to the immersed volume of the hull.

- Midship section. For ships, this section is located midway between the fore and aft perpendiculars.

- Maximum Area section, the maximum area section is usually located behind the midship section. Its area is denoted Ax ($A_{xc}$).

- Prismatic coefficient ($C_{p}$). This is the ratio of the volume displacement and the maximum section area multiplied by the waterline length, $C_{p}= V_{c}/(A_{x}*L_{wl}$).

- Block coefficient ($C_{b}$), the volume displacement is now divided by the volume of a circumscribed block $C_{bc}=V_{c}/(O_{wl}*B_{wl}*T_{c}$).

- Centre of buoyancy, The centre of gravity of the displaced volume of water. Its longitudinal and vertical positions are denoted by LCB and VCB respectively.

- Centre of Gravity, The centre of gravity must be on the same vertical line as the centre of buoyancy.

- Sheer line, The intersection between the deck and the topside.

- Freeboard, The vertical distance between the sheer line and the waterline.

- Scale factor, The scale factor is simply the ratio of a length at full scale to the corresponding length at model scale.

Figure 5 shows the main dimensions measured of a hull.

2.2.1.2 Main Forces

When the hull is driving through the water, a resistance is developed. Under equilibrium conditions, when the boat is sailing at constant speed, in a given direction, the resistance has to be balanced by a driving force from the sails. Unfortunately, this cannot be created without at the same time obtaining an aerodynamic side force, which in turn has to be balanced by a hydrodynamics side force. The heeling moment from the aerodynamic force is balanced by the righting moment from the buoyancy force and the weight. In Figure 6 the apparent wind direction is marked by a larger arrow. This is not the true wind direction, since the wind felt onboard the vessel is influenced by its speed through the air. The wind created by the boat speed is opposite to the arrow shown as boat speed in Figure 6.

Figure 6

2.2.1.3 Resistances

At low speed the dominating component is the viscous resistance due to frictional forces between the hull and the water. The friction gives rise to eddie of different sizes, which contain energy left behind the hull in the wake. This component increases relatively slowly with speed, as opposed to the second component, the wave resistance, which occurs because the hull generates waves, transferring energy away. The sum of viscous and wave resistance components are the upright resistance.

2.2.1.3.1 Viscous Resistance

The molecular forces between the hull and the water are strong enough to stop the relative motion in the innermost water layer. The part of the flow within the hull and the point in which the water velocity have the ship speed is called boundary layer. Near the bow the flow within the boundary layer is smooth. The velocity in one layer is slightly larger than in the layer just inside. After a certain distance from the bow disturbances start to occur, and shortly thereafter the flow structure breaks down into a seemingly chaotic state: turbulence. The boundary layer is now characterised by eddies of different sizes and frequencies. The fluctuating velocities caused by eddies are, however considerably smaller than the mean velocity at all points in the boundary layer, so the flow is moving backwards. A special region can be distinguished in the inner part, called the viscous sublayer. It plays an important role, particularly in connection with surface roughness. In the viscous sublayer the flow is mainly laminar, but is sometimes disturbed by turbulent bursts, located at isolated spots, moving downstream with the flow. The region where the flow changes from laminar and turbulent is called the transition region and is very short. The viscous resistance can be divided in three parts:

- The direct friction on the smooth surface

- The pressure imbalance between the fore and after-bodies

- The increase in friction due to surface roughness

Equation \ref{eq:one} and equation \ref{eq:two} show how to calculate the frictional resistance:

\begin{equation} R_f=0.5c_fρV_{e}^{2}S_w \label{eq:one} \end{equation}

where\begin{equation} c_f=\frac{0.075}{(Log(R_n)-2)^{2}} \label{eq:two} \end{equation} $V_{e}$ is the velocity of boat in $m/s^2$, $v_{vis}$ is the kinematic viscosity in $m^2/s$ and $S_{w}$ is the wet surface. A slightly lower pressure is found at the stern, giving rise to the resistance component, which is indirectly caused by friction, through the boundary level. It is in the range 5-10% of the direct frictional force. This value depend on the slope of the diagonals, that need to be about 25°. In order to minimise the viscous resistance the hull should have a shape like a cod, but very slender. The Cp should be less than 0.5 and the LCB should be positioned in front of the midship section. We can assume the viscous pressure is 10% of the friction, which is a reasonable for our purposes. [Lars Larsson, Rolf Eliasson, 2000].

2.2.1.3.1 Wave Resistance

When a sailboat is in the water it creates a wave system with well-defined properties, called the Kelvin wave system, and is due to a traveling point disturbance on the water surface. There is a very simple relation between wavelength and traveling speed for surface waves. Since the wave system travels with the boat, at the same in the longitudinal direction, the length of the generated waves will depend on the nautical speed.

Equation \ref{eq:three} is displaying the calculation of the wave speed. \begin{equation} wavespeed= \sqrt{\frac{gλ}{2π}} \label{eq:three} \end{equation} where λ = wavelength measured in metres and g = gravity measured in metres per second squared. After this the wave resistance can be calculated with a coefficient table depending on water-plane area, displacement, length on waterline and beam on waterline.

2.2.2 Mast

The mast is the structural point at which connects the hull to the sail and can come under large amounts of stress and strain. These fluctuating values calls for extra design care, the masts holds forces caused by the wind attacking the foretriangle. This is the triangular area formed by the deck, foremast, and headstay of a sailing vessel, this area must not be greater than 1.6 times the area of the mainsail. The sail area is greater than the righting moment divided by 128 times the heeling arm. The heeling arm is the length difference between the center of buoyancy before and after heeling is caused and created a moment.

- To calculate the rig we begin calculating the righting moment RM at 30° of heel in fully load condition.

- From the formula we get the transverse load values of $T_{1}$, $T_{2}$, $T_{head}$, $T_{boom}$. This will be done in Equation \ref{eq:four}, \ref{eq:five}, \ref{eq:six}, \ref{eq:seven}, \ref{eq:eight} and \ref{eq:nine}

\begin{equation} T_{1} = R_m/a_{1} \label{eq:four} \end{equation} where $a_{1}$=distance from hull and top of the mast in meters \begin{equation} T_{2} = R_m/a_{2} \label{eq:five} \end{equation} where $a_{2}$ = the height of the geometrical centre of the reefed sail in meters \begin{equation} T_{head} = 0.40 T_{2} \label{eq:six} \end{equation} \begin{equation} T_{boom} = 0.33 T_{2} \label{eq:seven} \end{equation}

- Calculate $T_{hu}$, $T_{hl}$, $T_{bu}$.

\begin{equation} T_{hu} = T_{head}d_1/(d_1+d_2) \label{eq:eight} \end{equation} \begin{equation} T_{bu} = T_{boom}BD/l_l \label{eq:nine} \end{equation}

- With this values calculate the dimensioning forces F1, F2, F3 depending on the number of spreaders,in Load case 1 and in Load case 2.

- Calculate the tensions of the shrouds in Load Case 1. Pd1, Pd2, Pv1, Pv2, Pd3.

- Calculate the tensions of the shrouds in Load Case 2. Pd1, Pd2, Pv1, Pv2, Pd3.

- Choosing the maximum value we get the dimensioning shroud forces : Pd1, Pd2, Pv1, Pv2, Pd3.

- Get the dimensioning forces Pfo and Pa.

- Knowing the material of the mast and the way it's stepped,Calculate for each panel's transverse moment of inertia Ix.

- Calculate the required longitudinal moment of inertia Iy.

- Entering values we get the requirements for the boom's section modulus.

- Entering values we can pick the relevant shrouds, stays and rig component, and the dimensions.

All the formulae are provided in the book “Principle of Yacht Design” and are referred to a normal sail. However they could be adapted for our wing sail.

2.2.3 Sail

For the design of our boat we decided to use a rigid sail. One of the benefits of using a single sail is the easier control by a micro-controller. Additionally the increased controllability has the effect that the boat can safely stay for a long time alone offshore. As a result we searched for different rigid wing sails to understand the newest technologies and decide upon the most profitable for our boat. We have attached some examples of these sails below:

2.2.3.1 The AC72 Catamaran (Oracle Team USA)

The rigid wing sail of this catamaran is 130 ft (40 m) tall. Flaps on the trailing edge provide lift and consists of multiple segments to shape the wing in order to match the wind and control the power. [Boats.com, 2013] These class of catamarans “AC72” or its smaller versions “AC45” are using a special design for their wing sails, which enables them to achieve top speed up to 1.6 times the speed of the wind sailing downwind. This is possible because by the increasing speed the catamaran gets lifted out of the water. As the drag through the water reduces as well, the boat will hardly touch the surface of the water anymore. [telegraph.co.uk, 2013]

Figure 7 displays the oracle catamaran sail

2.2.3.2 Wally Omer Wing (WOW)

- High performance in terms of boat speed and heading angles.

- Ease of handling by one person only, whatever its dimension is.

- Lowering and reefing characteristics.

- Reducing and simplifying the boat structures thus improving the interiors.

- Simple, safe and reliable.

The WOW Sail increases the performance by 10-30% in any condition, depending on the displacement of the boat: the lighter the boat is, the more efficient the wing sail is.["Wally", 2015]

Figure 8 shows the WOW Sail

2.2.3.3 X-Wing Wingsails

These sails are made of foam reinforced with sheet aluminium and plywood and are covered with clear heat-shrink plastic. The forward piece has an aluminium spar inside and a custom base with blocks for wing adjustment. The aft section has a “T” shaped control bar on the bottom that is used to trim the wing and a block beneath for the mainsheet. The top of the forward wing section has a knob toward the aft edge and the aft wing section has a tab with a hole that rests over the knob. It is secured with a pin and bolt at the bottom. The angle between the two wing sections is controlled by a single line rigged as a continuous loop. Release the cleats and pull on one side while easing the other and the aft wing section will move relative to the forward section, establishing the overall shape of the wingsail.["Tom", 2012]

Figure 9 pictures the X-Wingsails

2.2.3.4 Harbor Wing Composite

The design was realised using a variety of composite materials selected to combat the harsh marine environment and minimise weight. High-modulus HR40 carbon fibre material was selected for the stub axle to provide maximum tensile stiffness. The wing sail and tail parts are each fabricated in one-piece, on male mandrels, using E-glass wet out with epoxy resin and are cored with either core-cell styrene acrylonitrile (SAN) foam or aluminium honeycomb. Aramid fibre was incorporated into the wing leading edges for added impact resistance, and some carbon fibre was used in locations that required extra stiffness. The bulkheads are flat carbon fibre/epoxy plate stock, which is CNC-machined to shape. The wing tail arms are simple carbon/epoxy tubes. Secondary bonding was accomplished using epoxy.

Figure 10 displays the Harbor Wing Composite

2.2.3.5 How a rigid sail works

A rigid wing sail is not a new concept and works very similar to many aeronautical designs and applications. The rigid wing follows an airfoil shaped design, when in operation air flows faster on one side of the airfoil, this produces a high pressure which is known as Lift. Lift is the upthrust of the sail which is used to propel the boat and maintain speed.

Air also flows on the underside of the airfoil although here it flows at a reduced speed to the top surface, therefore at a lower pressure which is known as drag. Drag is the resisting force to lift, as the sail picks up speed and thus lift is increasing so must the drag value. A stabiliser flap can also be seen in Figure 11 this gives the wing extra stability and control on its mission, this flap can be controlled to improve course direction and recover from hazardous situations. Airfoils can be designed for a variety of applications in both land, sea and air. Although these environments can change dramatically the same concept still applies.

2.2.4 Keel

The keel is an important aspect of any boat design, while not all boats have a keel it stabilises boats that do. It prevents side wind capsizing the boat and although this is an advantage it may also cause the boat to run on ground, which depends on the depth of the water. Keels come in a variety of designs and weights and are usually custom to boats for their applications, below is a table representing these designs including there advantages and disadvantages:

2.2.4.1 Keel Selection

The main requirement that our boat has to fulfil is to be as much stable as possible. The keel that we need for our design will be the one that provides the most floatability for the boat. This means the centre of gravity has to be very low in order to avoid that the boat capsizes. To achieve this there are two different ways. The first one is designing a deep keel which works against the forces that attack at the sail and on the other hand it lowers the centre of gravity, which increases the buoyancy. The biggest disadvantage of a deep keel is that the boat will have limitations when sailing near the coast line. The second option is to put weight at the end of the keel. This lowers the centre of gravity without being too deep and improves the possibility to navigate everywhere. Lastly we have to mention that it is really important to not focus too much on the stability and weight of the boat because it will slow the boat down and also decrease its manoeuvrability. Summing up our investigations we come to the conclusion that a bulb keel would be the best design of our boat.

2.2.5 Rudder

Usually symmetrical shapes for the rudder are used to ensure when going straight, that there are no pressure differences between the two sides. If we go with the rudder at a certain angle there will be an asymmetric profile, this angle between rudder and fluid flow is called angle of attack. If we assume a fluid that flows at constant velocity that collides with the rudder, we firstly have two points to mention. These are the stagnation points where the velocity of the fluid is zero. The location of these points depend of the foil section and angle of attack in respect to the flow. To illustrate this you can see these stagnation points “S 1” and “S 2” in the following figure.

However, when sailing at higher velocities the flow at the trailing edge of the rudder will break away and cause a vortex to arise. This vortex will be between the stagnation point and the trailing edge. The rotation of the vortex will be always against the rotation that develops around the hull of the boat and depending on the viscous forces that are involved in this process. By holding a certain angle of attack, the vortex will break away and the stagnation point of “S 2” will move towards the trailing edge. By doing so the velocity differences of the upper and lower stream around the rudder are equalised at this point. There will be no more vortex and the stable flow will cause a lifting force.

Figure 13 displays the occurrence of vortex.

Figure 14 displays the lift force of the rudder

This lift force consists of two forces. One that is trying to move the boat in a certain direction and one that slows the boat down, due to acting backwards. The necessary physical basis for creating a lift is, that the upper stream of the fluid particles have to be faster that the ones that flow over the lover surface in order to reach the trailing edge at the same time. Furthermore we have to state that the higher the aspect ratio rudder is, the greater will be the lift created and faster the respond to a change in the angle of attack.

Another force to mention, that effects the performance of the rudder is called drag. Form drag always occurs when a fluid passes a solid object, as a resistance in the flow. This resistance is highly dependent on the shape of the rudder and will be minimised the thinner and smaller the rudder is. Apart from the form drag, we have skin friction. This is caused by surface irregularities of the rudder that slow down the flow of the fluid. To generate a smooth flow, called laminar flow, it is highly deepened on the angle of attack, the skin friction, shape of the rudder, velocity and the density of the fluid. At a certain point the flow will become turbulent which effects the lift created. The point at which the flow becomes turbulent is called transition point and is caused by a slow down in the velocity of the fluid flow around the rudder. The fluid will only accelerate until the suction point and loses momentum along its way.

Figure 15 displays the turbulence and different points causing drag.

Summing up the facts, we can state that the longer the laminar flow can be held, the less drag is caused. On the other hand the greater the laminar section of the rudder the earlier it tends to stall. The tendency of greater laminar sections to stall earlier but create a higher lift in small angles of attack can be seen in the following graphs (B has a greater laminar section). $C_{L}$ is the lift coefficient (y axis) and the x axis is the increase in the angle of attack.[Tom Lochhaas, 2015][B. Kohler, 2006]

Figure 16 displays the lift and point where the rudder tends to stall (max. point)

2.2.5.1 Rudder Conclusion

As a conclusion about the rudder design we want to use a symmetric spade rudder, that is designed after the principe of “NACA0012”. The “NACA0012” will provide high stall angle and the stall characteristics is gradual because it is less likely to cause cavitation and vibration. Furthermore the symmetric design will guarantee an equal working on the different angles of attack. As the rudder and the keel are working together, the rudder will contribute the necessary side forces for the keel and also will enable the boat to manoeuvre und all conditions. The rudder design will have to concentrate on the maximum side force required. This force is proportional to the product of the maximum lift coefficient and the plan form area. The nose of our rudder should be constructed like the purposed a) in the following figure. The graph is showing that the drag is increasing whether the nose is made blunter or sharper. Furthermore the shape a) will give the boat more lift which is essential for turning.

Figure 17 displays the rudder nose

2.3 Mechanical Principles

2.3.1 Hydrostatics

Hydrostatics considers the conditions of fluids in an equilibrium state, thus when fluid velocity is equal to zero. In these conditions the submerged surface area of the hull is put throughout to different pressures which are depended on the depth and the weight of the fluid. We will account the value of gravity as $9.81 \frac{ m }{s^2}$. A special case occurs while dealing with a hydrostatic condition, the acceleration and viscous terms are ignored, and pressure is only dependent on gravity and density due to zero flow or flow at constant velocity. The boat hull has forces applied from above and below. The force from above is gravity, forcing the boat down and vice versa from below is the force in an upwards direction. It is the upthrust created by a higher pressure at a greater depth and finally the weight of the boat is a factor.

The equilibrium of a boat can be analysed in two steps. Firstly to understand the equilibrium in water, we describe the static equilibrium and from there onwards we will show what dynamic equilibrium means in relation to our autonomous sailboat. The equation defines that a submerged or floating object has two laws governed by a principle discovered in the third century. This is the Archimedes Principle, which is stating that: “Any object, wholly or partially immersed in a fluid, is buoyed up by a force equal to the weight of the fluid displaced by the object.” [Clifford A. Pickover, 2008]

2.3.2.1 Buoyancy

Archimedes' principles in practice indicates that there is a buoyant force exerted in the bottom surface which lifts the boat up, while the mass of the boat times the gravity are working against it. Imagine if we have a boat floating on the water without wind, tides or currents nor any other distracting environmental circumstance, then the following equation describes the relation between boat and water:

Equation \ref{eq:ten}

\begin{equation} M \times g = V_{total}\times \rho_{boat}\times g = V_{fluid}\times\rho_{fluid}\times g\\ V_{total}\times\rho_{boat} = V_{fluid}\times\rho_{fluid} \\ \frac{V_{total}}{V_{fluid}} = \frac{\rho_{fluid}}{\rho_{boat}} \\ \rho_{fluid} {>} \rho_{boat} \label{eq:ten} \end{equation}

In this equation M is the mass of the boat in kg, g is the gravity in $m/s^2$, V is Volume in $m^3$, $\rho$ is the density in $kg/m^3$.

To explain this equation, we know that the weight of the boat is a downwards force which acts at the centre of mass. Collinear to this force is the force of buoyancy acting upwards on the centre of buoyancy. The mass of the boat is equal to its total volume times the mean density of the boat times the gravity. This part of the equation has to be equal to the volume of the displaced water by the boat times the density of the water times gravity. It is important to mention that the density of the boat is the mean of all different materials used.

For a floating of the boat the density of water has to be always greater than the respective density of the boat to ensure the equation equals $0$. If this is not the case the boat will sink. If you imagine to put some weight unevenly on one side of the boat, the boat will sink deeper on one side, which will cause an increase in buoyancy force and equilibrium is retained. The buoyancy force will chance because the centre of buoyancy is changing and this causes a greater moment. The condition, in which the boat always moves back to, is called stable equilibrium and the movement is called righting moment or positive stability moment.[Fabio Fossati, 2009]

Therefore, Archimedes' Principle indicates that the volume of the displacement of fluid is equal to the volume of the boat surface volume, that is submerged in the fluid. This also indicates the identical weight in both fluid and boat.

Figure 18 displays the forces of buoyancy and weight of the boat at each centres when the vessel is in stable equilibrium [Fabio Fossati, 2009].

Water Environment Density and Specific Weight

In our circumstances the boat must be able to be deployed in any environment and for this all water environments must be considered. Due to liquids being nearly incompressible we can neglect the variation in density and assume it as a constant in hydrostatic calculations.

| Environment | Average Density (kg/m3) | Specific Weight (N/m3) |

| Sea Water | 1020–1029 | 10,050 |

| Water | 1000 | 9,790 |

2.2.3.2 Stability

After understanding the basics of static equilibrium we now want to focus on forces that we have to take in consideration in an actual environment. Firstly there are forces that could cause a moment along the longitudinal x-axis of the boat. This might be caused by weights unevenly added to one side of the boat or i.e. due to wind and waves. The force(s) will result in a heel of the boat and it will lose its static equilibrium. If the sum of the moments become zero, the boat will retain equilibrium at this angle. Furthermore the centre of buoyancy will change, due to a change of the mass of the boat under water. See Figure 19 and Figure 20.

Figure 19 shows a change in the centre of buoyancy.

Figure 20 displays the moment along the longitudinal x-axis of the boat.

In conclusion we can say that there is the state of equilibrium if the forces G and B are equal to zero and the moments occurring along the x-, y- and z-axis are zero too.

2.2.3.3 Centre of Gravity

Next we want to point out the importance of the centre of mass being as low as possible compared to the centre of buoyancy in case of our boat. This refers to the last paragraph about the moments. As the target is to project a boat that fulfils its long term missions offshore, it is needed to ensure stability and avoid capsizing.

If we compare the two possibilities: In Figure 21 we have the centre of gravity under the centre of buoyancy. [Fabio Fossati, 2009]

And in Figure 22 we have the centre of gravity above the centre of buoyancy. [Fabio Fossati, 2009]

If we now imagine the situation in Figure 23 that the centre of gravity is above the centre of buoyancy and the boat will be put under side forces. This will undoubtedly cause a heeling of the boat. At position c) we can still see that the angle of heeling is not big enough to flip the boat over. Instead the boat still tends to go back in its original position. If the forces become bigger and situation d) is present, we can see that both centres are in a collinear line. In this position equilibrium is retained again. Now it is nearly impossible to get the boat back in the sailing position. Next, with an increasing side force, we come to position e), which is only temporal. Pretty quickly the boat will lie upside down in the water, see position f).[Fabio Fossati, 2009]

Figure 23 pictures the roll of the boat when side forces increase.

To underline this movement, we can see in the following figure two graphs. Number one displays the situation when the centre of buoyancy is above the centre of mass/gravity and it is the other way around in graph number two. If we now compare the stability in a relation between the moment of resistance and the heel angle, we can see that the first option is much more stable than the second one. The heel angle is the angle between the waterline of the boat and the surface of the water after the movement towards side.[Fabio Fossati, 2009]

Figure 24 is the graph on the stability of boats depending on the centres of gravity and buoyancy.[Fabio Fossati, 2009]

This Figure shows, that the second option is very unstable and tends to capsize faster than the first option. In fact if the $R_m$ is crossing the y-axis, than the centre of mass and the centre of buoyancy are collinear. As shown in the graphs, after option 2 has crossed the y-axis, the moment of resistance is negative. That means the boat has no resistance when totally capsizing. It actually enhances turning upside down.

To explain why a boat is capsizing we need to define the term of the transverse metacenter, which is often stated as simply metacenter.

The significant effect of the metacenter is that if it is above the centre of gravity, the momentum will righten the boat to its former stable upright position. If the metacentre is below the centre of gravity the momentum will result in the capsize of the boat.[Mark Denny, 2009] As shown in Figure 25 the point of the metacenter is at the intersection of the line of BG and the line of the new centre of buoyancy B´. As the rightening arm, the distance from G to Z, is getting bigger, the larger becomes the distance from G (centre of gravity) to M (metric centre). For heeling angles not greater than $10$ degrees the metacenter remains nearly constant. The distance of G to M at such small angles is called the metacentric height.[A.W.Carmichael, 2011] „The higher M is above G, the greater will be the value of GM, the metacentric height, and the righting arm, and consequently the greater will be the tendency of the log to right itself when slightly inclined from the upright position.“[A.W.Carmichael, 2011] The closer the metacenter is to the centre of gravity, the ship will change its stable equilibrium to a neutral equilibrium.

In Figure 25 we can see the position of the metacenter.

Figure 26 displays the positions of the metacenter and the stability of the boat. [Jonathan Ridley,Christopher Patterson, 2014]

2.3.2 Aerodynamics

The sail is the sustainable driving force of the boat, through the conservation of motion of wind to the sail. The sail controls many aspects of the boat thus vital in the design to ensure correct operation, balance and stability, while controlling both velocity and direction. Primarily the aerodynamic forces apply from differences in air pressure, causing normal stress which acts perpendicular to the sail and air viscosity. This causes a parallel shear stress on the entire sail surface. The boat is subjected to six degrees of freedom listed in the next section. The sail is subjected to lift and drag, shown in the figure below:

Figure 27

The image indicates all forces applied to a symmetrical section, which acts as a wing sail. It can operate for angles of attack ranging from 0-90 degrees, where lift and drag propel the boat as air pressures pass the winged section. This requires high levels of accuracy from the National Advisory Committee for Aeronautics (NACA), formally known as NASA. Some of their leading aeronautics experts published wind tunnel analysis's of winged section over 60 years.

The NACA wings vary in size and geometry and through the years of testing, they have distinguished sizes by allocating numbers. An example for this is the wing NACA 0012. The first two digits 00 indicate the aerofoil is symmetrical and the last two, for example 12, which means 12%, indicates the maximum thickness of the wing 15% behind the nose. These can vary from 6% to +24%. These NACA aerofoils will vary in our selection for the final design as testing and calculations must be carried out before finalising a stable wing for the boat.

These aerofoils produce a large quantity of drag, but conversely a larger lift coefficient. This lift coefficient or Ct, is in relation to the angle of attack. It can be depicted below for a NACA 0012: Figure 28

The graph shows a rise and fall of the lift coefficient to a maximum angle of attack up to 16 degrees. This wing gives values of three different Reynolds numbers for each section of the wing due to roughness. In this area the wing has an optimum effectiveness at 16 degrees. Although wing sails can operate when it is deeply stalled, the coefficient of lift always goes against angle of attack for the range 0 to 90 degrees.

To ensure aerodynamic stability the wing must move freely in the required direction, an additional symmetrical wing stabiliser can be installed on the wing. This allows the wing to balance and stabilise is wind direction and wing orientation changes. The aerodynamic forces are exerted onto the pivots and this brings two forces and moments into existence. These forces must have equilibrium with the stabiliser providing an upward force to balance the combined moments on the wing and on itself and to do this it must make an angle of attack in the same direction as that of the wing.

The wing and control vane in our circumstance the rudder is capable of producing a force to drive the boat and it is simple to switch and change tacks. If mounted on ball races it can respond to slow changes in wind direction. It is then a wing sail. The wing sail interacts with the wind to produce lift and drag in order to drive the boat. The orientation of the boat can be changed to accommodate wind forces applied. At the end we can state that a wing sail is much less cumbersome in comparison to a soft sail for our design.

It is possible to calculate the force applied on a wing sail at any point of sailing if the ratio of lift to drag is assumed, the effect of this ratio can be shown below:

Equation \ref{eq:eleven}

\begin{equation} ratio = {{Lift} \over {Drag}} = {L \over D} = {{Cl} \over {Cd}} = {1 \over {\tan (\alpha)}} = {d \over h} = {{distance} \over {height}} \label{eq:eleven} \end{equation}

.

It can be seen that lift and drag are both separate equations. Firstly the lift coefficient (Cl) and secondly drag coefficient (Cd) are both determined on complex dependencies of shape, inclination, and some flow conditions. Both coefficients have been tested extensively which has produced a vast array of Reynolds numbers for certain airfoil dimensions in wind tunnel conditions.

Equation \ref{eq:twelve} displays the lift coefficient.

\begin{equation} Cl = {{2L} \over {\rho{{\rm{V}}^2}{\rm{A}}}} \label{eq:twelve} \end{equation}

.

In this equation L is the lift of the airfoil in $N/m$, $\rho$ is the density in $kg/m^3$, A is area in $m^2$, V is the volume in $m^3$.

Equation \ref{eq:thirteen} displays the drag coefficient.

\begin{equation} Cd = {D \over {\rho A {{{V^2}} \over 2}}} \label{eq:thirteen} \end{equation}

In this equation D is the drag of the airfoil in $N/m$, $\rho$ is the density in $kg/m^3$, A is area in $m^2$, V is the volume in $m^3$.

These calculations are used to find the driving force of the boat, which can be incorporated into the next section of dynamic equilibrium, where the correct scales and dimensions must be ensured for the boat to float and not to capsize. When designing the wing it must be noted that there can be no net moment produced by the wing sail because it is free to rotate on its bearings. The physics behind wing sails allows it to be a viable concept. We will use the symmetrical NACA 0012 concept for our wing sail as its concept is considered available. Only the certain modification of the wing for our boat will be required to ensure a more efficient product.

2.3.3 Dynamic Equilibrium

After understanding what equilibrium means in terms of a vessel and what the forces are that prevent a vessel from capsizing, we now have to analyse the equilibrium when wind, currents and tides etc. are taking influence on the sailboat. Whenever the boat is in motion and other external forces are influencing the stability of the boat and it is preserving a point of equilibrium, we call it dynamic equilibrium. If you imagine a boat in the sea when it gets windy and the waves are rising, you actually see that boat rather moving along all directions. It tends to go upwards and downwards, from left to right. Putting that movements into description we can define them as following:

Figure 29 displays the effect of forces on the boat.

With understanding this, we can state that the dynamic forces arise from the relative motion of the boat such as wind and water. Firstly, we have the force of the wind which will be called $F_{A}$ in Figure 30. This force applies directly to a point called centre of the sail plan or aerodynamic centre of effort. To make it easier, we say that the centre is the geometrical centre of the sail, which is not always correct because it highly depends on the direction of wind and the trim of the sail. There are lots of variables to take into consideration. The force has a big component in the direction perpendicular to the wind direction and a small component towards the wind direction.[Fabio Fossati, 2009]] Apart from the aerodynamic forces we have the hydrodynamic forces. These forces occur under the water and are called $F_{i}$ in Figure 30. $F_{i}$ applies to the centre of lateral resistance. For simplify reasons it is in the centre of the longitudinal centre of the submerged part of the boat. If we imagine the boat in motion in water, it the centre of lateral resistance will depend on many variables i.e. the position of the rudder and trim of the sail. $V_{A}$ is the wind speed at and acting angle of $ß$. This is the course which the sailboat would intend to sail. The speed of the boat is assumed to be $V_{S}$. [Fabio Fossati, 2009]]

Figure 30 shows the hydro- and hydrodynamic forces on the boat.

The angle of the sail has the purpose to generate the biggest lift and minimise the drag of the boat, depending on the wind speed and angle. When combining the lift and drag force you get the total aerodynamic force as shown in Figure 30. The total aerodynamic force can be divided into the driving force $F_{M}$ and the aerodynamic side force $F_{LAT}$. This force $F_{Lat}$ is the heeling force. To get equilibrium the hull has to generate an equal force in opposite direction. This is possible with the use of the rudder to create an angle of attack (Lambda). In conclusion to the dynamic equilibrium we have the forces of the aerodynamic part, the hydrodynamic and the forces acting on the centre of gravity and centre of buoyancy. To create an overall dynamic equilibrium we have to ensure that:

Equation \ref{eq:fourteen} displays the sum of all forces and moments that have to equal $0$ to be in equilibrium.

\begin{equation} \sum_{}F_x=0~ \sum_{}F_y=0~ \sum_{}F_z=0~ \sum_{}M_x=0~ \sum_{}M_y=0~ \sum_{}M_z=0 \label{eq:fourteen} \end{equation}

In this equation F refers to the forces in x-,y- and z-axis and M refer to the moment in the axis as mentioned previously in this chapter.

2.4 Optimal Sail Position

To start off by explaining the best positions for sailing, we want to define the different possible sailing directions. The main distinction is between port and starboard direction. Anytime the wind is coming form the direction of the port side, the boat is going on port tack and the other way around. The exception is when the position is head to wind, then the boat will be either on port or starboard tack.

Figure 31 shows the different points of sail.

As you can see in Figure 31 there is a „No Sailing Zone“, which is the angle that a sailboat cannot sail, respectively to the wind direction. No sailboat can sail directly facing the wind and going towards its direction. The size of the „No Sailing Zone“ depends on the boat itself with its design, its sails and rig, but also on the strength of the wind and the waterbody. Depending on all these factors the zone may vary from 30 to 50 degrees either side of the wind. If a sailboat gets into the „No Sailing Zone“ the driving force will decrease and as the boat will not have enough forward momentum through the water, it will stop. On the other hand if the momentum decreases the rudder will also lose its force to steer the boat. When a boat tries to sail against the wind it will as called „tack“ through the „No Sailing Zone“. In order to do so the boat needs a higher momentum to turn in this area. In case the boat will lose steerage way before it exits the zone, it is „in iron“ and tends to stop, go backwards or return to the original tack. Another position of the boat can be „close hauled“ which means that the sailing boat is sailing as close as possible to the „No Sailing Zone“. This sailing direction is also called „upwind“. Next there is reaching which is travelling perpendicular to the wind. Whenever you are travelling toward the wind it is called „close reach“ whereas going away from the wind direction is „broad reach“. As soon as you sail at a right angle towards the wind it is called „beam reach“. Lastly if the wind is coming directly from behind you are „running downwind“. [Tom Cunliffe, 1994] The run position is on the other hand the only way that is possible to sail, which we will try to avoid. The reason for this is, that this is the most unstable way to sail. In order to find the shortest and quickest way to get to your target destination it is more difficult with a sailing boat than a motorised vehicle where the straight line is the shortest and best way to go. For sailing boats this route might not even be possible to sail if the target is in the „No Sailing Zone“ so called “upwind”. In this case the sailor has to beat windward.

For analysing the best sail trim we can first state, that there are three main types of wind. First there is the boat wind. This is the wind that you can feel when you are for example motoring through water with no wind to sail. This will always go strait from the bow to the stern as you drive forward. The next type of wind is the true wind. To find the direction of the true wind you can look for flags on buoys, boats at anchor or wind waves. The third type of wind is apparent wind, which is the combined boat wind and true wind. It lies between the two other types of wind and the main sheet trimmer should trim the main sail parallel to the apparent wind to give a good lift and drive. [Wikipedia, 2015]

Figure 32 displays the sail position in the apparent wind.

As the wind direction is very likely to change and can be changed into a virtually infinite number of sail positions, we want to use a smaller additional wing called „tail“, that is mounted just behind the main wing. Aircrafts for example also use a tail to control the exact angle of attack of its wings. In the same way our tail on the wing sail system is able to control the thrust obtained from the wind and will automatically take into account any changes in wind direction.

To get an idea of the boat behaviour and influence of the wind you do a polar diagram. In a polar diagram the maximum speed of the boat for every course relative to the wind direction is plotted for different wind speeds. To get a first impression of the boat behaviour we used the polar diagram of the „ASV Roboat“ that has been tested on the Lake Ontario, Canada in a 7 hours test with wind angles from 0 to 180 degrees and a wind speed up to 8 m/s. This will help us to get an idea for the speed prediction because it is quiet similar from its dimensions to our boat. [Roland Stelzer, 2012]

Figure 33 shows a polar diagram. [Roland Stelzer, 2012]

As you can see the speed of the boat drops to zero as it is getting closer to the „No Sailing Zone“ and also the „No Sailing Zone“ is decreasing as the wind speed increases. This polar diagram can be furthermore used as the basis for the routing strategy because it indicates the fastest angles for getting from a defined point A to B taking into consideration the sail position and the wind direction. Our approach to the optimal wing position is that the wing flies at a constant angle of attack to the apparent wind. That is, if the hull were held fixed, the wing would fly at a constant angle of attack relative to the true wind, and that angle of attack would be determined uniquely by the angle of the tails. This will allow us to get the optimal angle to the wing of the wing sail automatically by adjusting the tails. As we already pointed out the aerodynamic forces on the sail and that the apparent wind is a vector resulting from the true wind force and the velocity of the boat, we come to the following figures and ideas that are related to the scientific article [Gabriel Hugh Elkaim, Lee Boyce Jr., 2007] .

Figure 34 displays the boat with the vector forces and its sail adjustments.

- Top left: beating up wind, angles for a port tack (true wind from the forward left)

- Top right: reaching across wind, port reach (true wind from the left side)

- Bottom: running down wind, port run (true wind from the left rear)

To start with the first figure beating up wind we can state that the sail and tails are to be stationary at an angle of $0$ degrees. In this case the boat will stop and not moving forward by the wind force. If you want to go forward you need to move the tails now to an angle of $-\delta_{t}$ pointing with the edge to the direction of the true wind. This movement will cause the sail to rotate in this case clockwise at an angle of $\alpha$ and create a lift (L) perpendicular to the true wind and a drag (D) which is parallel to the true wind. The result of L and D is the force of the movement going forward called “R” . R can now also be defined as a perpendicular ($R_{\bot}$, creating heeling moment and a parallel ($R_{\parallel}$, creating the thrust component. As the boat moves forward the apparent wind will move towards the front. When this is happening the tail will have to keep the wing sail at a constant angle of attack ignoring the arising apparent wind. In the second Figure we can see the same behaviour as in the first. The tail will have to move at an angle of $-\delta_{t}$ towards the wind, creating a movement of the main sail and thus creating a velocity and also a movement of the apparent wind towards the bow of the boat. In the last Figure we can see the same process as in the previous figures only that the tail will be in front of the boat. Nevertheless the angle of attack of the wing sail will remain constant. If the wind would now come from the opposite side of the boat (starboard) the angles and movements will only be mirrored at the new angle $\delta_{t}$. [Gabriel Hugh Elkaim, Lee Boyce Jr., 2007]

2.5 Obstacle Protection

Obstacle Protection is another part that has a great influence on the sail position. Therefore we investigated on possibilities to avoid obstacles. One suggestion we found is described in the following.

The basis for the obstacle protection is the polar diagram. Due to the fact that the diagram displays the maximum speed possible at a given wind speed and sail angle towards the wind, it is possible to reduce the speed if obstacles are sensed in the surrounding area of the boat. In the following Figure 35 you can see the systematic. The outer circle which is named $\gamma _{max}$ is the so called „safe horizon“. If an obstacle occurs outside this circle it has no influence on the course the ship is going ($O_{4}$). In terms of the polar diagram the boat speed will not be changed. If an obstacle is inside the inner circle it has on the other hand the maximum impact on the speed of the boat. This will lead to a decrease of speed and if necessary to fully stop ($O_{3}$). If obstacles are between those areas they will have an impact on the speed of the boat depending on the distance to it. To define which are the most important obstacles on the way to its destination, the surrounding area will be decided into equally sized sectors. For each sector the distance to the nearest obstacle is sensed. [Natalie Wittinghofer Christian Alt, 2011]

Figure 35 displays the idea for the obstacle protection.

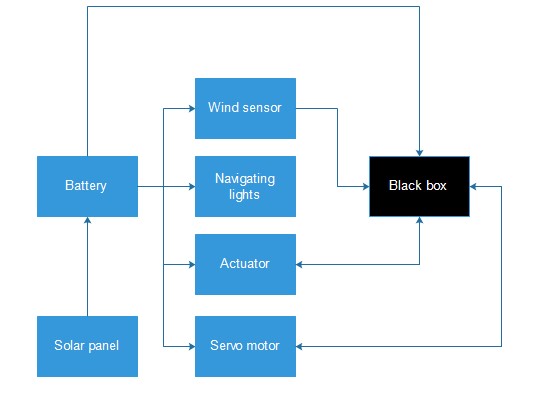

After defining the mechanical principles, and introducing the optimal sail position and obstacle protection, we will now continue with the electrical devices that we think have to be considered to put into the boat to collect the necessary data. These devices are important to control the sail at the end and calculate the best angle to sail, with all environmental influences taking into consideration.

2.5 Electrical Devices

2.5.1 Batteries

Batteries have one thing in common, they can store and provide electricity. Additionally they can contain any number of cells, which have a chemical unit inside. There are many types of batteries with different capacities. A battery's capacity is the amount of electric charge it can deliver at the rated voltage in Ampere-hour (Ah) or Watt-hour (Wh). For our project we will need a source of energy that supplies the different electrical devices with power. As the devices use the power of the battery, we will also have to think about ways to recharge the battery when in use. This can be done by solar, sea and wind. Although these forms of natural energy will not be developed in this project we will have to consider them to ensure the boat is fully self sufficient in both sustainably and Eco-efficient aspects.

Table 9 shows different types of batteries.

Conclusion: The best battery type for our boat is the Li-Ion battery. It has high energy density, a good lifespan, and less charging hours than the other battery types [Explainthatstuff!, 2015] [Battery University, 2015].

2.5.2 Solar Panel

A Solar Panel is a device, which can convert the sun generated electromagnetic radiation to electrical energy. Basically a solar panel is a collection of solar cells and these cells work together to produce electricity. There are three main solar cell types: amorphous, mono-crystalline, and polycrystalline solar cells.

Table 10 shows different types of solar cells.

Conclusion: The best solar cell for our boat is the polycrystalline solar cell. This is the most widely used type, and it has a good energy efficiency, and it is not too expensive. [Energyinformative, 2015] [C Changes, 2015].

2.5.3 Sensors

Sensors are one of the most important measuring elements in the field of electronics. Although we used to use them mainly for different measurements in the control engineering, nowadays we use them in the consumer electronics as well. This measurement is a comparison between the measuring and etalon. However, there are many types of sensors, we only need three different types of sensors: a wind sensor, a compass sensor, and a GPS receiver. [52] [Luc Jaulin Fabrice Le Bars, 2013] [Joshua Earnest, 2014].

2.5.3.1 Wind Sensor

A wind speed sensor is part of an instrument that is used to measure the speed of the wind and determine wind direction. Depending on the wind sensor we choose, the sensor can also generate electrical energy as a backup supply.

Table 11 shows different types of wind sensors.

Conclusion: The most suitable wind sensor at this stage of our investigation is the AMS AS504X encoders. It is very small and cheap, and supported by Arduino.

2.5.3.2 GPS Receiver

The Global Positioning System (GPS) is a satellite-based navigation system made up of a network of 24 satellites placed into orbit by the US Department of Defence. GPS was originally intended for military applications, but in the 1980s the government made the system available for civilian use. GPS works in any weather conditions, anywhere in the world, 24 hours a day. GPS receiver compares the time a signal was transmitted by a satellite with the time it was received. The time difference tells the GPS receiver how far away the satellite is. Now, with distance measurements from a few more satellites, the receiver can determine the user's position and display it on the unit's electronic map. [57]

Table 2 shows different types of GPS receivers.

2.5.3.3 Compass Sensor

The compass sensor device can be used to determine direction refer to magnetic north. Just like real compass, a compass sensor can be affected by large metallic objects and magnetic interference caused by motors and computers.

Figure 38 displays a compass sensor.

Honeywell HMC5883L: Triple Axis Compass Magnetometer Sensor Module for Arduino. This is a surface-mount, multi-chip module designed for low-field magnetic sensing with a digital interface for applications such as low cost compassing and magnetometry.

Features and benefits:

• 3-Axis magnetoresistive sensors

• Includes 12 bit ADC converter

• Built in self-test

• Low voltage operations (2.16 to 3.6 V) and low power consumption (100 μA)

• Sensors can be used in strong magnetic field environments with a 1° to 2° degree compass heading accuracy

• Compatible for battery powered applications

• Price: ~ €3

2.6 Related Work

2.6.1 Projects

2.6.1.1 ASV Roboat

The ASV Roboat is a nearly 4 meter long boat with a 60 kg keel ballast to achieve that it is unsinkable. In the year 2008 the ASV 'Roboat' became the first world robotic sailing champion at an event in Austria. It has a 800 MHz/512 MB Mini-ITX computer that is controlling the electrical devices with the use of software like Java and C++. Furthermore it has GPS data for the positioning and can estimate the speed of the boat. Also on board there are sensors like ultrasonic wind speed and direction data, tilt-compensated compass, humidity, air and water temperature and water depth. Additionally the boat has a three-stage communication system combining WLAN, UMTS/GPRS and an IRIDIUM satellite communication system for navigation and tracking. For the energy supply they added solar panels, which makes the boat mostly energy independent. As a backup they used a direct methanol fuel cell. [58] The battery with the solar panels are providing up to 285 W of power and the direct methanol fuel cell delivers 65 W for backup power. The sail area of mainsail and foresail together is around 4.5 $m^2$. [59]

This project of the ASV Roboat can be compared to our project this semester, as their approach was to build an unsinkable boat as well. On the other hand the main goal of the boat is speed and going from a defined starting point to an end. However, due to the successful engineering process that won already championships, we can orientate our project along this boat.

Figure 39 displays the ASV Roboat

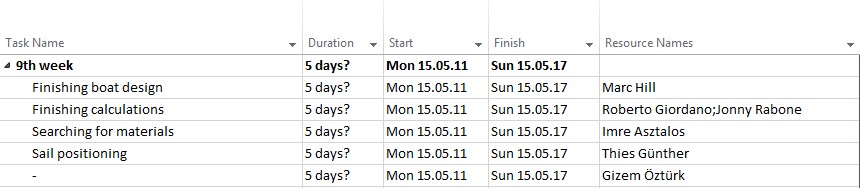

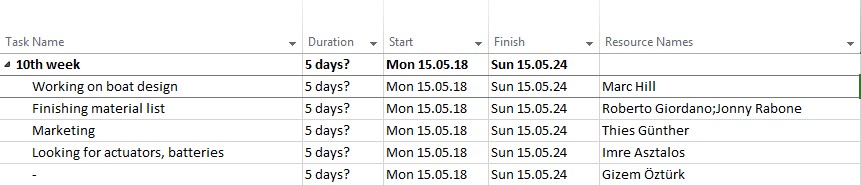

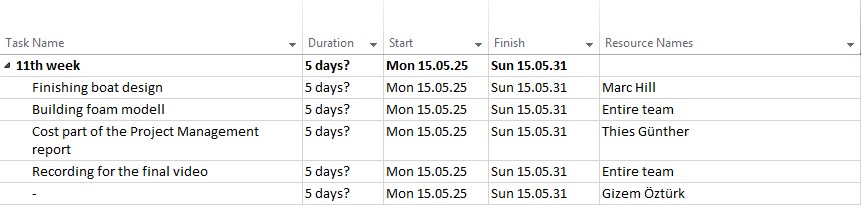

2.6.1.2 Saildrone